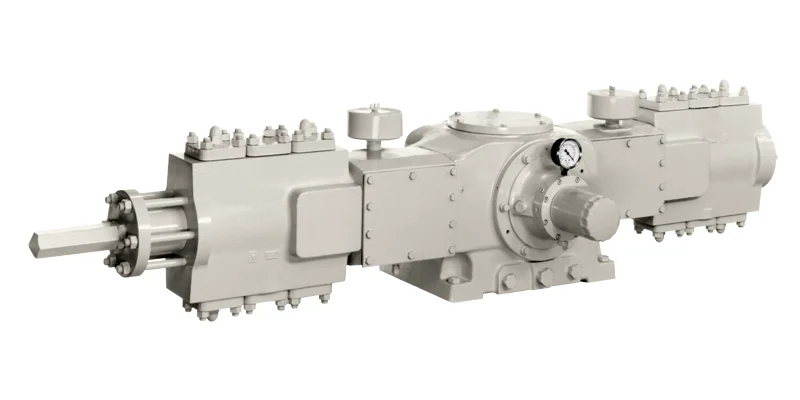

Using the same field proven design of the Knox Western model TP200 compressor, Knox Western has now developed two units available with 3.0" or 4.5" stroke crankshafts, for direct couple or V-belt drive.

Number of throws

2

Horsepower

200

RPM (min - max)

550 - 1500

Frame lubrication

FFL

Stroke

3.5

Piston speed (fpm)

874

Crankshaft Centerline (inches)

-

Overall length, (max.) (inches)

-

Overall length, (max.) (inches)

-

Approx. weight (frame only) (lbs)

500

Rod Loads, (tension) (lbs)

9,000

Rod Loads, (compression) (lbs)

9,000

Rod Loads, (combined) (lbs)

18,000

Oil pump capacity (gpm)

-

Crankcase oil capacity (gal)

2.5

Oil Pressure (min - max) (psig)

35 - 60

Crankpin diameter (in)

3

Main bearing diameter (in)

5.12 x 1.22

Piston rod diameter (in)

1.125

Number of throws

2

Horsepower

200

RPM (min - max)

550-1800

Frame lubrication

FFL

Stroke

3

Piston speed (fpm)

900

Crankshaft Centerline (inches)

-

Overall length, (max.) (inches)

-

Overall length, (max.) (inches)

-

Approx. weight (frame only) (lbs)

500

Rod Loads, (tension) (lbs)

9,000

Rod Loads, (compression) (lbs)

9,000

Rod Loads, (combined) (lbs)

18,000

Oil pump capacity (gpm)

-

Crankcase oil capacity (gal)

2.5

Oil Pressure (min - max) (psig)

35 - 60

Crankpin diameter (in)

3

Main bearing diameter (in)

5.12 x 1.22

Piston rod diameter (in)

1.125

Number of throws

2

Horsepower

200

RPM (min - max)

550-1200

Frame lubrication

FFL

Stroke

4.5

Piston speed (fpm)

900

Crankshaft Centerline (inches)

-

Overall length, (max.) (inches)

-

Overall length, (max.) (inches)

-

Approx. weight (frame only) (lbs)

500

Rod Loads, (tension) (lbs)

9,000

Rod Loads, (compression) (lbs)

9,000

Rod Loads, (combined) (lbs)

18,000

Oil pump capacity (gpm)

-

Crankcase oil capacity (gal)

2.5

Oil Pressure (min - max) (psig)

35 / 60

Crankpin diameter (in)

3

Main bearing diameter (in)

5.12 x 1.22

Piston rod diameter (in)

1.125

COMPONENT

MATERIAL

Crankcase

Grey iron Class 40

Bearing housing

Gray cast iron Class 30

Flywheel

Carbon steel

Crankshaft

Ductile iron Class 80/55/06

Main bearings

Double row spherical roller

Connecting rods

Ductile iron Class 60/40/18

Wrist pin

Alloy steel AISI 8602

Wrist pin bearings

Bronze

Crossheads

Ductile iron Class 60/40/18

Crossheads guides

Grey cast iron Class 30

Piston rods (rolled threads)

Alloy steel AISI 4140

Cylinders, low pressure

Grey cast iron Class 40

Cylinders, medium pressure

Ductile iron Class 60/40/18

Cylinders, high pressure

Forged steel

Pressure packing

Non-metallic, full floating

Pistons, low pressure

Aluminum SAE 355

Pistons, medium pressure

Grey cast iron Class 30

Pistons, high pressure

Integral with piston rod

Valve seats and guards

Carbon steel

Valve springs

Stainless steel or chrome vanadium

Note specific TFE blend to be determined per application. Our management system of standards is designed and reinforced to assure the quality of all operations and processes. Our continuous improvements apply to both quality and environmental requirements.

The TP is a low horsepower line of compressors and was designed to meet a wide range of compression requirements. This compressor offers single and multistage applications to 6500 PSIG.

TP Series can be configured with distance pieces and special materials. It comes with a single, 2 and 4 throw configuration frame. The TP model can be splash lubricated or force feed lubricated.